Divisions / Process Analyzer Division

Process Analyzer Division

Advanced solutions for chemical and physical monitoring of industrial processes

A process analysis system is a complex system designed to detect chemical or physical characteristics of a given sample within the process itself.

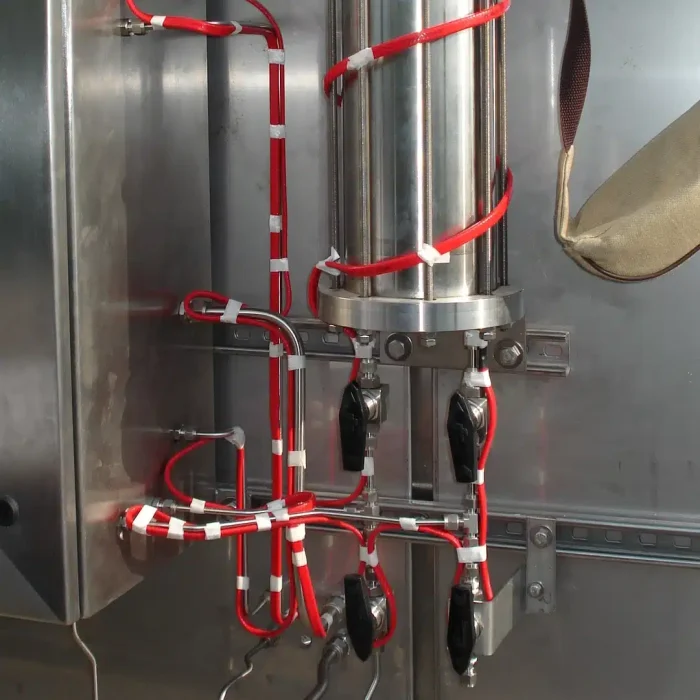

Apart from inherent solutions that require application conditions consistent with the requirements of the specific analyzer (not always achievable), an analytical system generally consists of an analyzer and all the devices that allow the sample to be continuously fed to the analyzer and treated in such a way as to meet the physical requirements of the analyzer without altering the property to be measured (sampling probes, sample pre-treatment, transport line, filtration and fast loop, final treatment, etc.).

In addition to the appropriate analytical technology (extremely important, but not exhaustive), the system must be engineered on a case-by-case basis based on the characteristics of the process itself (composition, pressure, temperature, etc.). Therefore, various assessments of the sample’s behavior on its way to the analyzer must be made in order to maintain its representativeness with regard to the property to be analyzed.

Need a customized solution?

Principal

Products

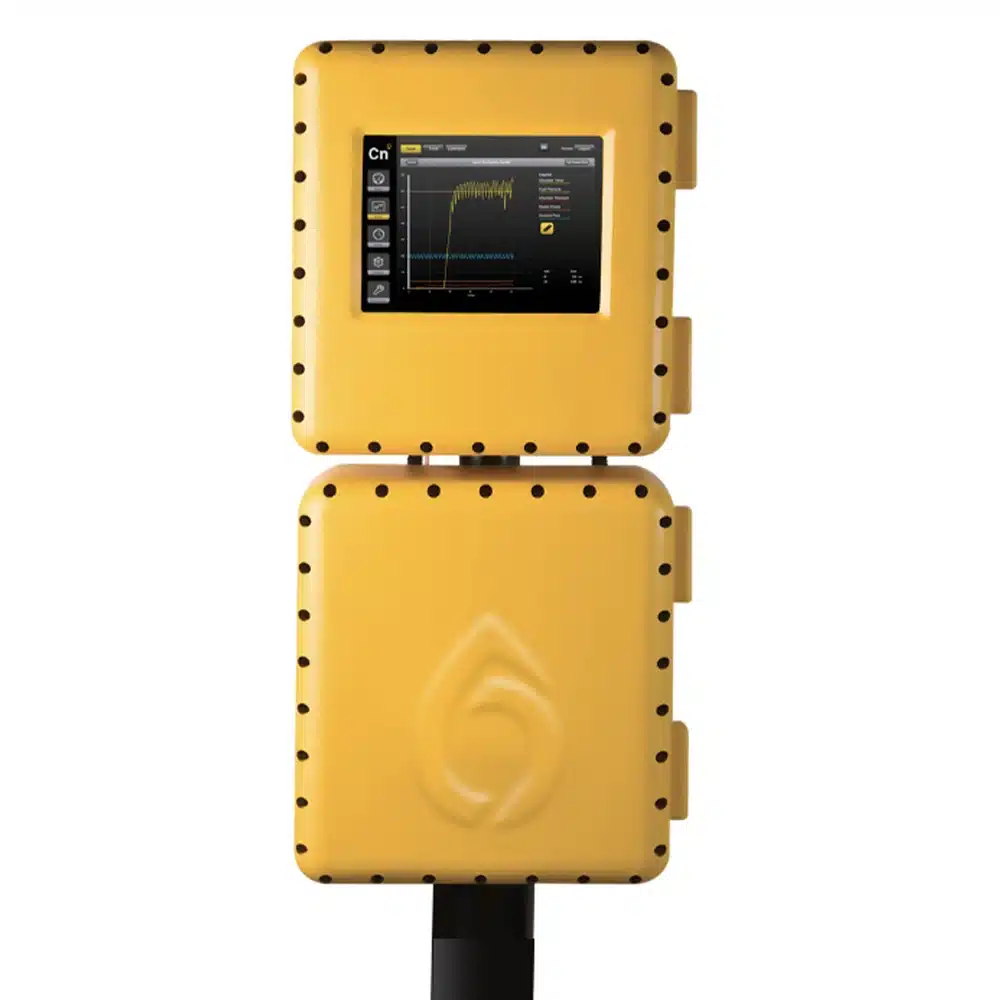

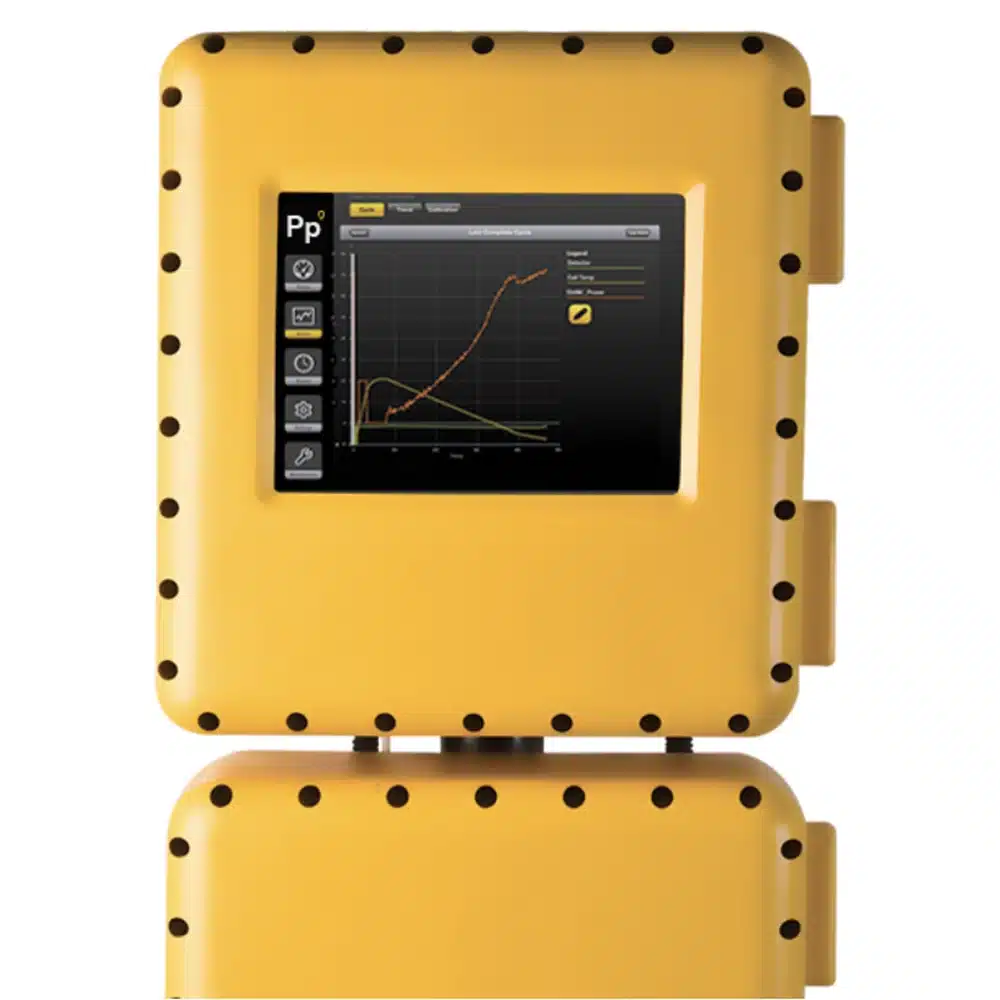

Calorimeters

The control of furnaces and burners varies depending on the requirements and type of heater or boiler. However, the thermal load of the furnace and the air/fuel ratio are two critical parameters that must always be monitored and controlled. Depending on the type of control system, the Wobbe index, lower heating value, and gas density may also be required as inputs.

TDLAS laser spectrometers

FTIR spectrometers

The properties of a blended product (whether gasoline or diesel) must be monitored in real time during blending to ensure compliance with specification requirements. The analyzer to be used must therefore have the following characteristics:

- high accuracy

- very fast analysis times to allow for any corrections to be made to the recipes online

- compliance with ASTM requirements for accuracy

- self-validation

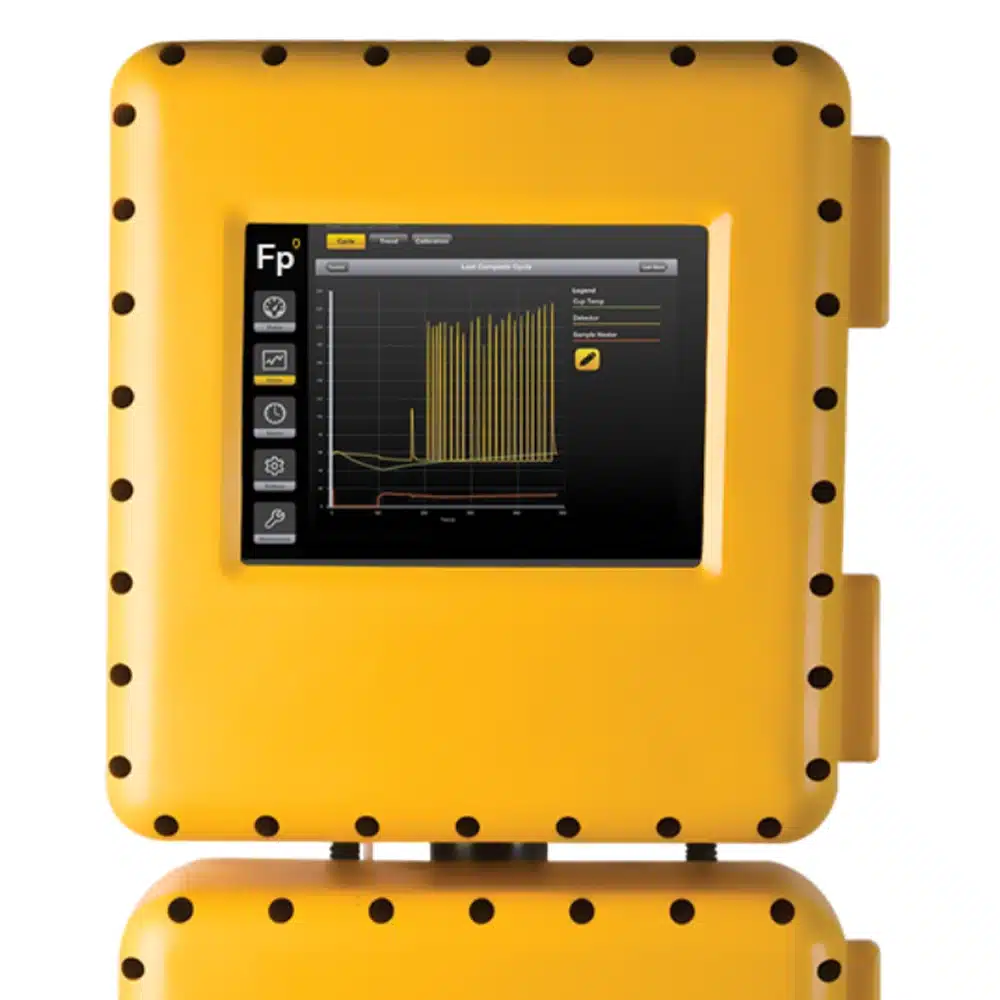

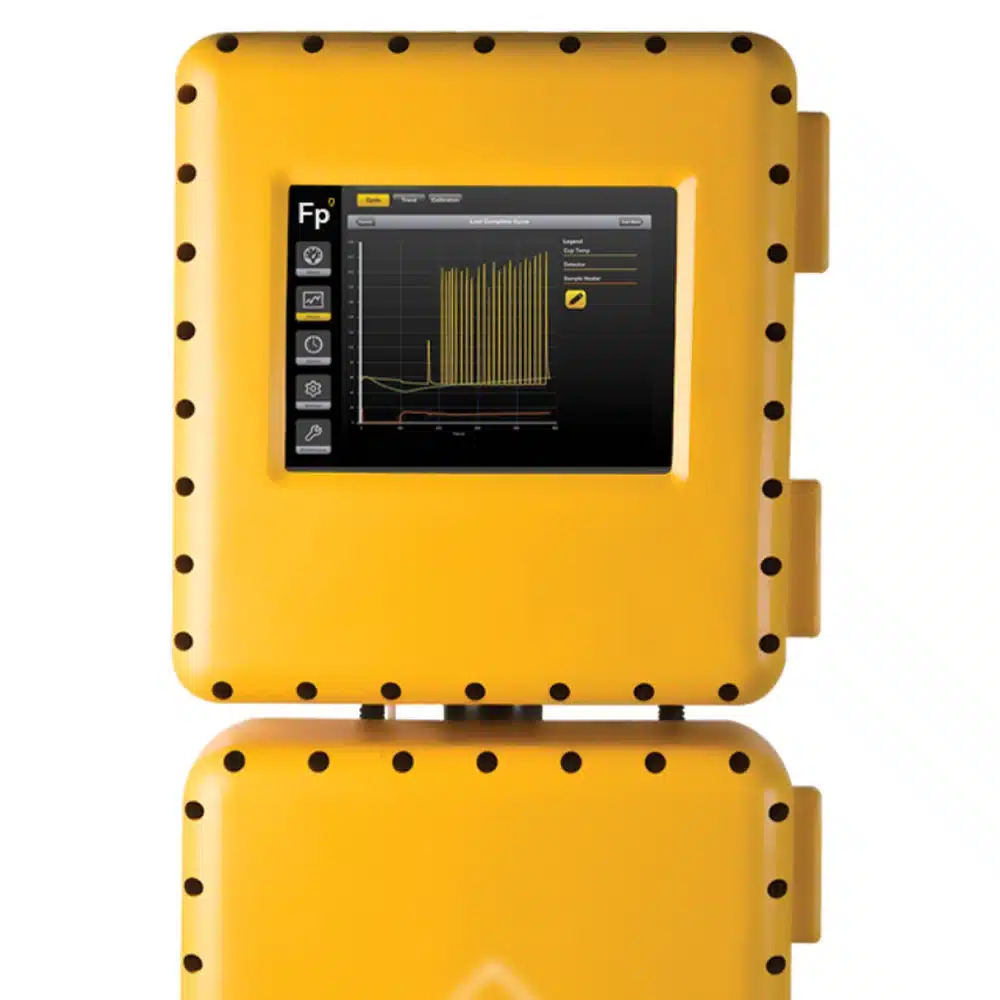

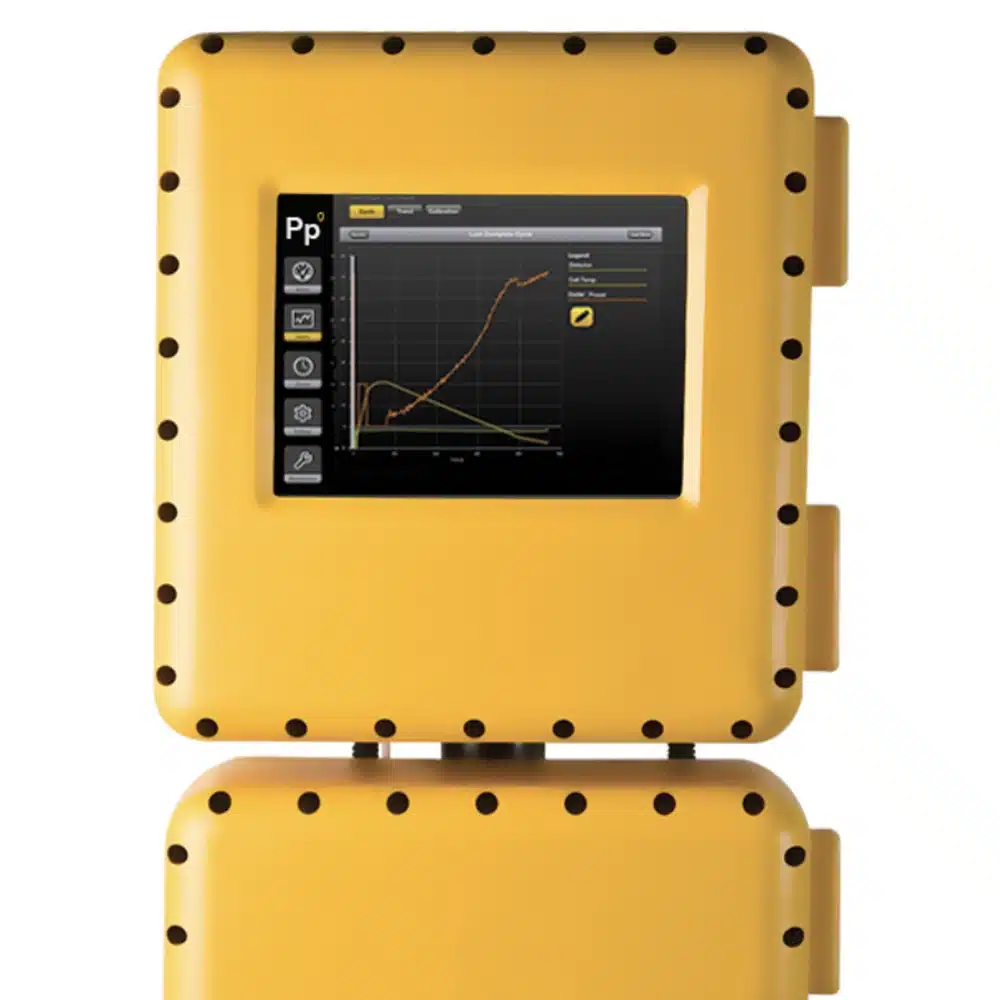

ASTM online analyzers

ASTM (American Society for Testing and Materials) standards determine the methods for measuring the main physical properties of products. These standards are often mandatory for the qualification of finished petroleum products in accordance with specific requirements. In particular:

Mass spectrometers

Mass spectrometry allows the concentration of chemicals in a sample to be determined by measuring the quantity of molecules with a defined mass, ionizing the chemical compounds to generate molecular fragments, and measuring the signal intensity derived from those molecules with the desired mass.

Gas chromatography

Gas chromatography is widely used in chemical and petrochemical analysis to separate and analyze the components of a gaseous or vaporizable mixture. Typical applications include the search for pollutants in a pure sample and the determination of the complete composition of the mixture. Socrate offers a range of traditional and miniaturized process chromatographs covering a wide range of applications.

UV spectrometers

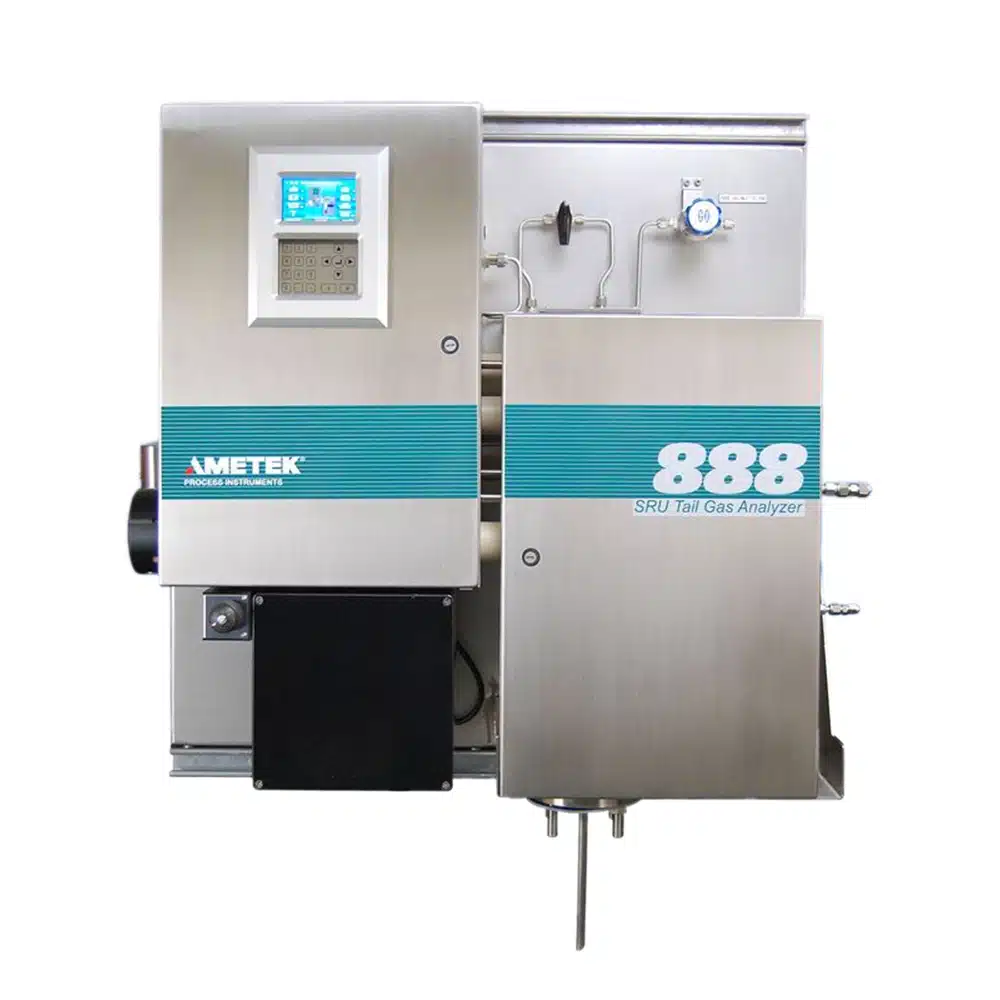

Analytical systems based on ultraviolet spectrometry for monitoring sulfur compounds, specifically designed for applications in natural gas and sulfur recovery plants. Using a spectral range that is not affected by the presence of water vapor, they are ideal for monitoring wet processes even with high dew points.

Zirconium Oxide O2 Analyzers

Monitoraggio idrogeno

H2scan fornisce soluzioni per rilevamento perdite di idrogeno e di monitoraggio di processo più accurate, flessibili e convenienti per un’ampia gamma di applicazioni nell’industria energetica, nell’industria di processo industriale e per l’economia dell’idrogeno. La tecnologia brevettata di sensori di idrogeno a stato solido è supportata da 15 anni di ricerca e sviluppo e 10 anni di verifica sul campo e vendita al dettaglio. Le nostre soluzioni per l’analisi dell’idrogeno e il rilevamento delle perdite affrontano i numerosi limiti tipicamente associati alle tradizionali tecnologie di rilevamento dell’idrogeno e offrono in modo esclusivo i seguenti vantaggi rispetto alle soluzioni tradizionali.Il sistema di rilevamento si basano su una tecnologia a stato solido brevettata in grado di rilevare e misurare l’idrogeno senza false letture o necessità di costose apparecchiature accessorie.

Analisi dell'umidità e punto di rugiada

Varie applicazioni richiedono una misurazione continua e affidabile dell’umidità in bassissime concentrazioni (ppm) in gas e vapori. I nostri analizzatori forniscono al cliente una misura diretta della concentrazione di umidità e con un grado di accuratezza e sicurezza che altri analizzatori non possono offrire. Inoltre possiamo fornire analizzatori del punto di rugiada che forniscono elevate prestazioni con un interessante”rapporto qualità-prezzo”.

Efficienza della combustione

L’efficienza della combustione fornisce informazioni utili per la conduzione del bruciatore in modo che sia utilizzato la minor quantità di combustibile per fornire la temperatura desiderata nonché del fatto che tutto il combustibile venga correttamente ossidato, ottimizzando il processo. Tale informazione viene determinata dalla corretta percentuale di ossigeno nel forno specie se combinata con la misura di componenti incombusti quali CO e H2 (comunemente definiti come COe).

Zolfo totale

Anche se lo zolfo elementale non è tossico, i suoi composti come il di solfuro di carbonio, l’idrogeno solforato e l’anidride solforosa invece lo sono. La presenza di zolfo in un gas o in un liquido deve essere misurata per determinare i composti di zolfo che si possono sviluppare durante il processo, il trattamento o il suo utilizzo. Un analizzatore di zolfo in linea determina il contenuto totale di zolfo dei campioni in fase liquida o gassosa, sostituendo attività di laboratorio costose e complesse una cui gestione non corretta potrebbe portare ad alterazioni del risultato.

Gas naturale

Applications

Ammonia systems

Sulphur recovery plants

The Sulfur Recovery Unit (SRU) is an essential plant for recovering sulfur compounds present in gas and oil, which are separated from the crude product during the refining process.

Dehydration plants

Moisture in technical and process gases, as well as in natural gas, can affect both the quality of the gas itself and the infrastructure related to its transport or use.

Monitoring the moisture content (even in very low concentrations) is therefore vital both for qualifying dehydration plants and the gas itself in order to guarantee its usability.

Desulfurization plants

In the refining of petroleum products, an important stage of product treatment is the removal of sulfur, which by law must not exceed thresholds that vary from product to product and from state to state.

Emissions monitoring and combustion control

Monitoring of finished products according to ASTM

As a result of the refining processes, the products must meet specific requirements in terms of physical and chemical properties.

Flare gas monitoring

The discharge of process gases into a flare is required in many chemical and petrochemical plants to limit the direct emission of flammable, explosive, and toxic components into the atmosphere. When the gas is not discharged into a flare, it is essential that it is flushed with inert gas to prevent oxygen (air) from entering the pipe, which could generate a source of ignition in the presence of flammable and explosive gases.

Natural gas and biomethane quality

At the points of entry into the national gas network, it is essential to monitor not only the quantity but also the physical and chemical characteristics of the gas injected, for both fiscal and quality purposes.

H2 production, blending, and deblending plants

Hydrogen production presents one of the main challenges of the decarbonization era, both in terms of safety and monitoring the quality of the gas produced, its concentration in other carrier gases such as natural gas, and its extraction and purification.

Accurate hydrogen measurement requires selective and specific technologies that allow measurements to be taken independently of the gas matrix in which hydrogen is measured.

Ni-Pa solid-state technology, such as Laser TDLAS technology, allows selective detection of H2 molecules with minimal maintenance and response times that are extremely faster than chromatographic technologies.

Systems

Case Study

Provers

SYRIAN PETROLEUM COMPANY – Siria

Liquid measurement systems with Positive Displacement Meter and relative conventional

Natural Gas Metering System

GREENSTREAM – Libia

GAS measurement system with three 20” 600# ultrasonic measuring lines.

Mobile Calibration Unit

SONATRACH – Algeria

Compact (small prover) trolley for calibration according to the master

Natural Gas Metering System

SAIPEM – Italy

Gas measurement system with 3 measurement lines with 24“ 600#

Fuel Gas Metering System

Yinson Production / ENI – FPSO Ghana

Gas measurement system with 2 measurement lines with ultrasonic meters.

You will be contacted within 24 hours.