Divisions / Fire & Gas

Fire & Gas Division

To work well, you need to work safely

For this to be truly possible, it is essential to choose partners with qualified and experienced personnel and excellent products: Socrate S.p.A. can guarantee this to all its customers. Socrate S.p.A. has been manufacturing Fire & Gas systems for decades, using state-of-the-art control units and instrumentation to ensure that its customers are alerted promptly so that they can get to safety and minimize damage to the plant. The world of “Fire & Gas” refers to systems and technologies designed to detect the presence of flames, toxic and explosive gases in the environment. These systems are essential for ensuring safety in various sectors, such as industrial, chemical, oil and other environments where there are risks associated with combustion and the emission of hazardous substances. Here is an in-depth look at some key aspects:

Flame detection

Flame detection involves the use of sensors that can detect the onset of flames or fires. These sensors can work in various ways:

- Infrared (IR) detectors: These sensors detect the emission of infrared radiation emitted by flames.

- Ultraviolet (UV) detectors: Some systems use UV radiation, which is emitted by many flames, to detect fires.

- UV/IR combination: Some detectors combine both technologies to increase accuracy and reduce false alarms.

Detection and quantification of toxic and explosive gases

Gas detection systems are designed to monitor the presence of hazardous gases, which may be toxic or explosive. These systems use different types of sensors:

- Semiconductor sensors: These sensors measure changes in electrical resistance in the presence of specific gases.

- Infrared sensors: Used to detect gases such as methane, carbon dioxide, and many others, they exploit the absorption of infrared light by gas molecules.

- Electrochemical sensors: These sensors generate an electrical response in the presence of toxic gases, making it possible to detect them.

- Combustible gas detectors: These provide an indication of the accumulation of flammable gases such as methane or propane.

Thanks to the new infrared technologies offered by Socrate, it will also be possible to quantify combustible or toxic gas leaks using thermal imaging cameras (fixed or portable).”

Applications and importance

Fire & Gas systems are used in a variety of applications, including:

- Industrial plants: Factories, refineries, chemical plants, and more.

- Marine sector: On ships and offshore platforms where fire and gas risks are high.

- Commercial buildings: Protection systems for offices, shopping centers, and other structures.

Regulations and standards

The sector is regulated by specific safety regulations and standards, which vary depending on the country and sector, such as those issued by the Occupational Safety and Health Administration (OSHA) in the United States, European regulations, or Italian regulations Uni 9795.

Need a customized solution?

Principal

Solutions

Offshore platforms, pipelines & refineries, petrochemicals, LNG, compression stations, chemical plants, water & sewage treatment, tank farms, FPSO units, biomethane production, solar, wind and hydro energy, and green hydrogen production.

Products

Combustible gases

Catalytic principle, infrared technologies, metal oxide semiconductors, and electrochemical cells

Flame detectors

Leak detection

Ultrasonic technology

Thermal imaging cameras

RedLook technology

Continuous monitoring features

Gas Detection

High detection probability and low false alarm rates

Quantification of gas leaks

Detect, color, and quantify the mass flow rate of the leak

Flame detection

The most reliable early warning system for fires

Access security control

Next-generation security and protection features

Flare monitoring

Real-time performance monitoring and early detection of liquid carryover

Flare flame quality monitoring

Efficiency indicator for the destruction and removal of the smoke index warning

Flame control for ovens

Provide better viewing angles for oven tubes and check thermocouple performance

Temperature measurement

High-precision thermography-based automatic temperature control system

Gas Detection

High detection probability and low false alarm rate

With Sensia’s Optical Gas Imaging (OGI) cameras, you can automatically detect, color, and quantify methane, sulfur hexafluoride, and many other industrial gas leaks in seconds, accurately and safely, without having to shut down any systems. With Sensia OGI cameras, you can quickly scan large sections of equipment and detect areas that traditional contact measurement instruments cannot access. OGI cameras can also detect leaks from a safe distance, visualising these invisible gases as smoke clouds. This gas detection feature is available for both fixed systems and portable versions.

Quantification of gas leaks

Detect, color, and quantify the mass flow rate of the leak

With Sensia’s Quantitative Optical Gas Imaging (QOGI) cameras, you can automatically detect, color, and quantify methane, sulfur hexafluoride, and many other industrial gases in seconds, accurately and safely, without interrupting your systems. With Sensia’s AI-powered QOGI cameras, you can quickly scan large sections of equipment and detect areas that traditional contact measurement tools cannot access. The Caroline F Series and Mileva F Series can monitor all types of systems and trigger alarms when a fault or deviation in behavior is detected. Furthermore, RedLook’s algorithms are so precise and accurate that virtually no false alarms are triggered.

Flame detection

The most reliable early warning system for fires

RedLook “Flame Detection” is the most reliable tool for fire anticipation (using intelligent thermography) and early fire warning. Cutting-edge AI analysis provides excellent performance in terms of range, detection probability, and warning time. Capable of detecting fire risks before they break out, this reliable monitoring system offers high immunity to false alarms. It understands the most common sources, such as sun reflections, moving lights, or fluctuating hot lamps.

Access security control

Next-generation security and protection features

RedLook Surveillance is an integrated end-to-end tool that enables the next generation of people monitoring capabilities in security and safety applications associated with the most advanced Sensia thermal cameras. The RedLook Surveillance tool combines the most advanced thermal image analysis and processing with machine learning, resulting in an unmatched intelligent monitoring product.

Flare flame monitoring

Real-time performance monitoring and early detection of fluid passage

Real-time functionality is configured by the user with the optimal level for each glare in the field of view of the Sensia camera. If a suboptimal situation is detected, an alarm is generated on all user interfaces and logged.

Flare flame quality monitoring

Efficiency indicator for the destruction and removal of the smoke index warning

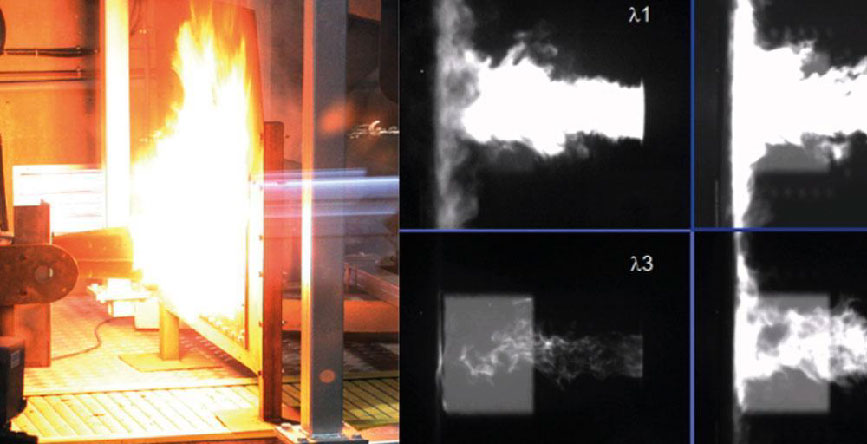

Flare Efficiency is a real-time RedLook feature supported by Sensia cameras that provides users with highly detailed information on the combustion efficiency (CE) of industrial flares. This feature is based on proprietary multispectral radiometric analysis.

Flame control for ovens

Provide better viewing angles for oven tubes and check thermocouple performance

Flames block information hidden behind the fire. The RedLook Furnace Inspection application allows you to recover thermographic data while ignoring the flames. Sensia’s spectral filtering goes beyond the fire, opening up a wide range of applications. Having a clear view in hazardous areas is essential for industry (steel, industrial furnaces), safety (fire departments), and laboratory testing under real fire conditions.

Temperature measurement

High-precision thermography-based automatic temperature control system

Sensia technology offers an automatic temperature control system based on high-precision thermography. Long-range, high-precision temperature measurement is essential for optimizing performance and efficiency in industry. On the other hand, continuous monitoring of critical components is a step forward in preventive maintenance and early detection of malfunctions. RedLook can be integrated with other systems and allows you to set custom alarms that activate automatically.

Systems

Case Study

Provers

SYRIAN PETROLEUM COMPANY – Siria

Liquid measurement systems with Positive Displacement Meter and relative conventional

Natural Gas Metering System

GREENSTREAM – Libia

GAS measurement system with three 20” 600# ultrasonic measuring lines.

Mobile Calibration Unit

SONATRACH – Algeria

Compact (small prover) trolley for calibration according to the master

Natural Gas Metering System

SAIPEM – Italy

Gas measurement system with 3 measurement lines with 24“ 600#

Fuel Gas Metering System

Yinson Production / ENI – FPSO Ghana

Gas measurement system with 2 measurement lines with ultrasonic meters.

You will be contacted within 24 hours.